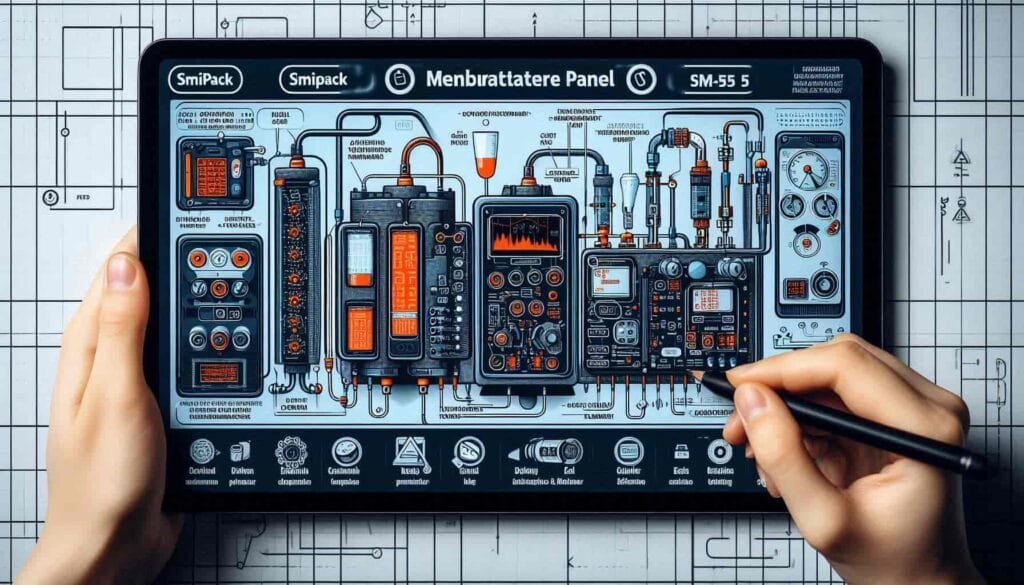

Designed for effective product packaging, the high-performance, user-friendly smipack sm-55 control panel membrane panel shrink wrapping machine Often found in retail, manufacturing, food, and pharmaceuticals, the SM-55 is well-known for its adaptability and small size. Managing the machine’s operations including settings for heat, speed, and wrapping technique depends critically on the control panel membrane.

Understanding the Control Panel Membrane

The main user access point for machine controls on the front of the smipack sm-55 control panel membrane panel is the control panel membrane, which sits here. It consists of a thin layer of flexible, touch-sensitive material that lets users change settings with merely button clicks, hence improving usability while preserving the machine’s small form.

Features of the SMIPACK SM-55 Control Panel

Important elements of the SMIPACK SM-55 control panel membrane consist in:

- Touch-sensitive buttons enable exact input with minimum effort.

- Show machine status, settings, and real-time data on digital displays.

- LED Indicators: Turn on to indicate alert operators to faults or active functions.

- Users of many control modes—manual and automatic—may change between several operational settings.

Importance of the Membrane Panel in Industrial Applications

The design of the membrane panel is perfect for industrial environments since it is easy to clean and robust. Membrane panels are less likely to wear and tear than conventional mechanical buttons, which is crucial for preserving constant performance in settings where the machine might run continually.

Key Benefits of a Control Panel Membrane

Membules of control panels have numerous benefits.

- Durability:Perfect for industrial settings because resistant to chemicals, dust, and moisture.

- Compact Design: The flat membrane panel fits quite well with the machine’s architecture.

- Improved User Interface: streamlines processes, hence lessens the requirement for intensive training.

Structure and Design of SMIPACK SM-55 Control Panel Membrane

Usually, the membrane panel comprises of numerous layers:

- Graphic Overlay: The highest layer with buttons and indications.

- Circuit Layer: In charge of registering pushes or touches.

- Spacer Layer:generates tactile feedback for button presses.

- Adhesive Layer: guarantees the membrane remains firmly bonded to the machine.

User Interface and Control Options

Clear labeling and well-placed buttons on the SMIPACK SM-55 control panel membrane allow easy access to critical controls, therefore facilitating simplicity:

- Power Controls:Simple press turns the machine on and off.

- Heat Settings: lets users vary the shrink wrapping temperature.

- Speed Controls:The conveyor belt should be set in speed to allow for varying material and size of goods.

These components facilitate operators’ ability to change settings to fit certain packaging requirements.

Customizable Settings and Automation

Different configurable settings made possible by the control panel membrane provide best performance:

- Preset Programs:A few SM-55 models let customers save preferred settings for jobs involving repeat packaging.

- Automatic Mode: helps to automate some packaging processes, therefore lowering hand involvement.

- Adjustable Timer: To guarantee consistency, operators can select exact time for shrinking and sealing purposes.

How the Membrane Panel Affects Machine Performance

The machine’s general efficiency is much improved by the membrane panel. The user-friendly and adjustable interface allows operators to easily change settings to satisfy production needs, hence lowering downtime and raising output. The touch-sensitive panel also reduces mechanical faults connected with conventional buttons.

Durability and Maintenance of Control Panel Membranes

Although they are engineered to resist great use, membrane panels nonetheless need regular maintenance to guarantee long-term endurance. Usually, maintenance involves:

- Regular Cleaning: Clearing the surface of dust and trash helps to stop harm.

- Inspection for Wear: looking for indicators of degradation, such buttons not working or fading images.

- Software Updates: Making sure any digital parts linked to the panel are current.

Tips for Prolonging Membrane Panel Life

To run a control panel membrane for longer:

- Avoid Sharp Objects:Use fingertips or specially made styluses instead of sharp objects to prevent harm.

- Regularly Clean with Soft Cloths: Gently dust and clean to prevent panel scratches.

- Train Operators Properly: Make sure every staff member can properly operate the control panel.

Troubleshooting Common Control Panel Issues

Operators might run upon problems including:

- Unresponsive Buttons: This can point to cleaning or recalibration required.

- Display Errors: Display flaws usually call for modest repairs or software upgrades.

- Faded Graphics: To guarantee usability and visibility, a fading graphic overlay could need replacing.

Regular maintenance and quick troubleshooting ensure the panel’s operation, therefore guaranteeing a seamless workflow.

Advantages of Control Panel Membranes Over Traditional Interfaces

Control panel membranes differ from conventional mechanical buttons in:

- Offer a More Streamlined Design: Both visually less complicated and easier to clean is the flat surface.

- Require Less Maintenance: Usually more robust and less prone to mechanical failure are membrane panels.

- Enhance Aesthetic Appeal: Skilled design choices enhance the general look of the machine.

Modern industrial machinery like the SMIPACK SM-55 choose membrane panels because of their several benefits.

SMIPACK SM-55 Control Panel in Comparison with Similar Machines

Although many shrink wrap machines use control panels, the membrane panel of the SMIPACK SM-55 is noteworthy for its extensive features and responsive design. With less mechanical components than models with conventional interfaces, the SM-55 is more efficient and user-friendly. Over time, this helps to prevent degradation. Furthermore notable in terms of flexibility and simplicity of use is the SMIPACK SM-55, which provides both manual and automated controls.

Conclusion and Future of Control Panel Membranes

The contemporary approach to user-friendly, robust machine interfaces is embodied in the SMIPACK SM-55 control panel membrane. Membrane panels are becoming more and more valuable in industrial machinery as packaging technology develops since demand for flexible, dependable, and simple control systems is rising. Digital displays, sophisticated touch capabilities, and flexible controls that meet different manufacturing requirements could all find even deeper integration in the future.

FAQs

1. The SMIPACK SM-55 control panel membrane serves primarily what purpose?

With choices to change temperature, speed, and other package factors, the control panel membrane helps users effectively operate and regulate the settings of the SMIPACK SM-55 shrink wrapping machine.

2. How might user experience be enhanced by the membrane panel?

The membrane panel improves simplicity of use and efficiency by offering a user-friendly interface with touch-sensitive buttons, clear labels, and simple access to machine controls, therefore simplifying operation.

3. Is one able to alter the control panel membrane?

Indeed, certain models let for preset programs, automation, and configurable settings—all of which are quite helpful for repeat packaging jobs and higher output.

4. The membrane panel needs this kind of maintenance?

Maintaining the functionality and extending the lifetime of the membrane panel depends on routine cleaning, inspections, and software upgrades.

5. Would control panel membranes outperform conventional buttons?

Among other benefits over conventional buttons, control panel membranes include enhanced longevity, lower maintenance requirements, and a more elegant design.