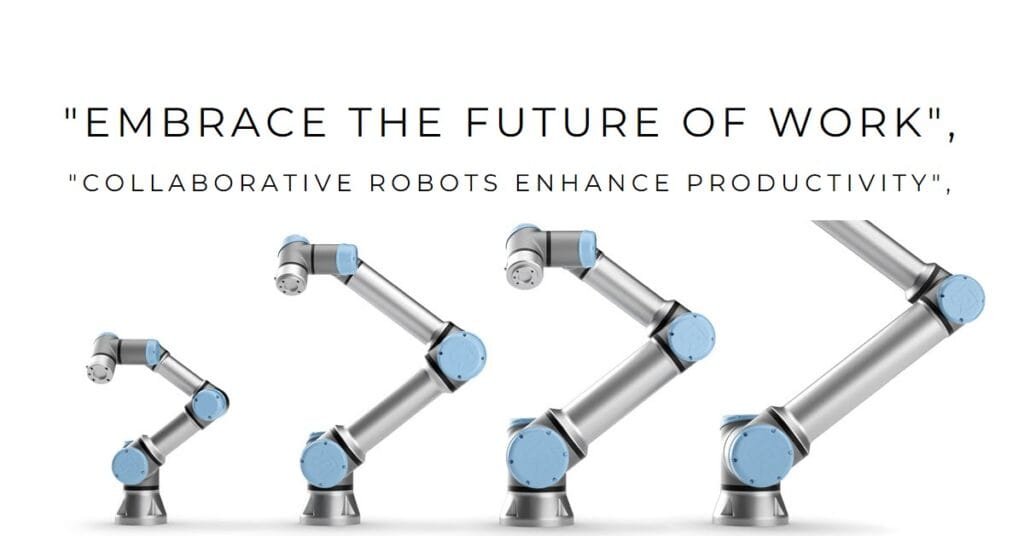

The requirement of human-robot cooperation is become increasingly important as sectors change. Leading edge of this revolution are cooperative robots, sometimes known as “cobots.Designed to coexist with people, collaborative robots enhance efficiency, safety, and output in many different fields. Built to engage directly with human workers, cobots share tasks and space without the need for protective barriers unlike conventional industrial robots, which run in isolated environments. This lets companies maintain worker safety while simplifying processes.

Modern sensors and safety mechanisms on collaborative robots help them to operate safely next to people. Their adaptability lets them handle anything from material handling and quality control to assembly and packaging. Working alongside people, these robots are revolutionizing sectors including manufacturing, healthcare, and logistics where they increase output and lower the risk of damage.

Cobots assist workers in production by doing repetitive chores such assembly and packaging therefore freeing them to concentrate on more difficult jobs. They support patient care, rehabilitation, and operations in the medical field. Cobotics help to increase material handling and sorting efficiency in logistics.

Through built-in force-limiting technology and automation of routine operations, cobots improve safety and boost output. Furthermore reasonably priced, they provide small and medium-sized companies with a reasonably priced approach to include automation into their operations. As cobots are adopted by businesses, the nature of employment seems to be more cooperative and effective.

What Are Collaborative Robots (Cobots)?

Definition of Collaborative Robots

Designed to operate safely next to human operators in a shared environment, collaborative robots—or cobots—are Unlike conventional industrial robots, which are sometimes isolated by safety barriers, cobots include sophisticated sensors and force-limiting technology that let them interact directly with people without running a danger. A major part of the future of automation since these robots are meant to help with jobs rather than replace human labor.

Key Features of Cobots

Cobots are easily programmed, lightweight, adaptable, and hence fit for a variety of uses. Usually including sensors, cameras, and sophisticated safety systems enabling their environment to be detected and reacted to, they This lets them collaborate with people without using defensive boundaries. Many cobots are also modular, which means they can be readily changed for a variety of tasks—from assembly and welding to packing and inspection.

Evolution of Collaborative Robots

Emerging as a solution to meet the rising demand for automation without replacing human labor are cobotics. While cobots were created to be more flexible and safer for human contact, classical robots were sometimes utilized for repeated, high-precision operations in isolated situations. Advances in artificial intelligence, machine learning, and sensor technology have over time improved cobots’ capacity to complete more difficult jobs in cooperation with people across sectors like manufacturing, logistics, and healthcare.

How Do Collaborative Robots Work?

Safe Human-Robot Interaction: Designed with built-in safety systems, collaborative robots guarantee they can interact peacefully with people. Modern sensors on them, including proximity detectors and force sensors, let the cobot sense human presence and modify its motions. Should a human approach too closely or a collision seem certain, the robot will slow down, stop, or veer off course. This dynamic reaction guarantees a safe workplace and helps to prevent mishaps.

Simple Programming: Cobots are notable for their simplicity of usage among other things. Many cobots are built with simple interfaces that let non-experts rapidly program them. Many times featuring drag-and- drop programming or teach pendant systems, these robots let people physically lead the robot through tasks. Small companies and sectors without specific robotic programming knowledge will find them easily because to their simplicity.

Integration with Existing Workflows: Highly flexible and easily fit into current processes, cobots cause least disturbance when included. From manufacturing lines to healthcare contexts, they are adaptable and fit for many environments. Cobots are perfect for companies that need constant process modification since they are made to be simply rearranged for various purposes.

Vision Systems and Sensors: Sensors and advanced visual systems let cobots complete jobs needing accuracy and flexibility. Based on real-time data, these sensors let the robot recognize objects, detect and negotiate obstacles, and even interact with them. Cobots’ capacity to “see” their surroundings allows them to function in dynamic environments and change with the times, therefore increasing their adaptability in many uses.

Types of Collaborative Robots

Light Payload Cobots

Usually under 10 kg, light payload cobots are made for jobs requiring handling smaller quantities. For jobs such assembly, pick-and-place, and packaging—where accuracy and adaptability are absolutely vital—these robots are perfect. Their modest weight makes them simple to include into small-scale production techniques. Electronics assembly, small part handling, and packaging processes in sectors including consumer products, food production, and pharmaceuticals are among common uses.

Heavy Payload Cobots

Usually ranging from 10 kg to over 100 kg, heavy payload cobots are bigger, more durable robots able of lifting and transporting greater items. Where great strength and endurance are needed, these cobots are meant to help with chores including car assembly, machine tending, and material handling. In sectors involving big, heavy components, they help increase production, therefore lessening the physical strain on human workers while also preserving accuracy and efficiency in tough conditions.

Mobile Collaborative Robots

Usually ranging from 10 kg to over 100 kg, heavy payload cobots are bigger, more durable robots able of lifting and transporting greater items. Where great strength and endurance are needed, these cobots are meant to help with chores including car assembly, machine tending, and material handling. In sectors involving big, heavy components, they help increase production, therefore lessening the physical strain on human workers while also preserving accuracy and efficiency in tough conditions.

Applications of Collaborative Robots

Manufacturing

Collaborative robots are widely used in manufacturing for tasks such as assembly, welding, material handling, and packaging. Their flexibility and precision make them ideal for industries like automotive, electronics, and consumer goods. Cobots can work alongside human workers, performing repetitive or physically demanding tasks, which increases productivity while reducing the risk of human error and injury. They can also assist in quality control and precision tasks, making them invaluable in high-demand production environments.

Food and Beverage

Cobots assist in food and beverage industry sorting, packaging, and quality control. Packaging plants employ them for jobs including filling containers, labeling, and defect inspection of goods. Their crucial capacity to manage delicate food products and operate in sterile surroundings helps to maintain hygiene standards and guarantees product quality. In food manufacturing lines, cobots also improve efficiency, aid to sort ingredients, and lower human contact.

Healthcare

Collaborative robots are having major impact on the healthcare sector. They provide accuracy and stability in sensitive operations, therefore supporting surgeons throughout operations. Hospitals’ surfaces are also cleaned using cobots, which also help to move medical supplies between departments. In the production of drugs, they guarantee great levels of hygiene and help with drug packing. Because cobots can manage monotonous chores, medical staff can concentrate on more important care, hence increasing the general patient outcomes.

Logistics and Warehousing

By automating jobs including sorting, transporting, and inventory management, cobots are transforming warehouses and logistics. Through less time spent on manual labor, they assist supply chain managers, logistics providers, and e-commerce businesses. Cobots guarantee faster turnaround times and lower the risk of mistakes by independently moving products around warehouses, improving order picking accuracy, and streamlining inventory control.

Agriculture

Cobots help in agriculture with chores including fruit picking, seed planting, and produce sorting. These robots improve yield management and automate time-consuming chores, therefore helping farmers boost efficiency. Harvesting delicate crops and doing repetitive chores that would otherwise demand a lot of human effort benefit especially from cobots. As technology develops, their application in agriculture is rising since they provide more exact and environmentally friendly farming methods.

Benefits of Collaborative Robots

Increased Efficiency and Productivity

Repetitive jobs like assembly, packaging, and material handling—that is, tasks that collaborative robots shine in constantly repeating performance. Cobots help human workers to concentrate on more difficult and value-added tasks by assuming over these mundane chores, therefore greatly increasing general productivity. This helps companies to keep high manufacturing rates, lower downtime, and simplify processes.

Enhanced Safety

Repetitive jobs like assembly, packaging, and material handling—that is, tasks that collaborative robots shine in constantly repeating performance. Cobots help human workers to concentrate on more difficult and value-added tasks by assuming over these mundane chores, therefore greatly increasing general productivity. This helps companies to keep high manufacturing rates, lower downtime, and simplify processes.

Cost-Effective Automation

Without safety cages or barriers, cobots are made to operate safely next to human workers. Having sophisticated sensors, they can identify human presence and, when needed, halt or slow down, therefore lowering the danger of industrial injuries. Cobots are perfect for settings where human workers and robots have to coexist since of this safety aspect.

Flexibility and Adaptability

Cobots have great versatility among other important benefits. From assembly to packaging to quality monitoring, they can be rapidly customized to do a range of chores. Their versatility qualifies them for many sectors, including automotive, food manufacturing, and healthcare. Cobots fit very well into new processes as companies change.

Improving Worker Satisfaction

Collaborative robots help to raise worker happiness by assuming repetitious, physically demanding jobs. Workers are free from boring chores so they may concentrate on more interesting and intellectually exciting ones. This raises job happiness as well as motivates and improves a staff.

Challenges of Collaborative Robots

Though collaborative robots (cobots) are easier to program than conventional industrial robots, the initial setup and integration might still provide difficulties. Companies could have to modify their current processes to fit cobots, and some could need specific knowledge to guarantee seamless integration into manufacturing lines. This can entail installing sensors, guaranteeing appropriate safety measures, and maximizing the robot’s performance for particular jobs.

Maintenance and Downtime: Cobots must remain running smoothly, hence regular maintenance is quite essential. Cobots nevertheless need regular check-ups to guarantee that sensors, motors, and other components are operating as they should even if their design is meant to be user-friendly. Cobots can suffer downtime without appropriate maintenance, which would lower production. Emerging to help solve this problem are predictive maintenance solutions, but companies still face constant difficulty.

Human-Robot Coordination: Although cobots are meant to coexist with humans, successful teamwork calls for careful design and training. Employees must pick up new processes and learn safe robot interaction techniques. This coordination might call for changes in work culture and the creation of new procedures to guarantee that both human employees and robots may operate effectively together.

Job Displacement Concerns: Though cobots help to increase output, there are questions over job displacement, especially for low-skilled individuals. Although cobots are supposed to help people instead of replace them, others worry that automation would cause less employment possibilities. Companies have to find a balance between keeping a qualified workforce and automating repetitive jobs so that staff members be retrained for more advanced responsibilities.

Real-World Examples of Collaborative Robots

Universal Robots (UR)

Leading proponent of collaborative robots (cobots), Universal Robots provides flexible and user-friendly solutions for sectors including automotive, electronics, and food processing. Known for simplicity, versatility, and capacity to operate securely with humans, their cobots—UR5 and UR10—are straightforward to program.

Rethink Robotics’ Baxter and Sawyer

Designed by Rethink Robotics, Baxter and Sawyer are recognizable collaborative robots. Particularly in small to medium-sized companies, these robots are appropriate for repeated activities including assembly, material handling, and quality inspection. Their built-in safety elements and flexibility make them perfect for hectic workplace.

Amazon Robotics

At its fulfillment facilities, Amazon has made considerable integration of collaborative robots. These cobots improve operational efficiency, inventory control, and product transportation thereby helping human workers. Human-rooted robot cooperation has transformed Amazon’s logistics.

ABB’s YuMi

Designed especially for precise jobs, such electronics assembly, ABB’s YuMi is a dual-arm collaborative robot. For complex production processes, YuMi is a unique option because of its ergonomic design, sophisticated motion control, and capacity to securely share workspace with people.

Future Trends in Collaborative Robots

AI and Machine Learning Integration

Advanced artificial intelligence and machine learning technologies are projected to be included into collaborative robots (cobots), which will help them to learn from their environment, adapt to challenging jobs, and over time increase productivity. This development will enable more freedom in uses including assembly or inspection.

Advanced Vision and Touch Sensors

Enhanced sensory systems integrating 3D vision and haptic feedback in next-generation cobots will enable exact manipulation and safer interactions with people. These developments will increase their use in delicate operations such surgical support or electronics manufacture.

Increased Use in Small and Medium-Sized Enterprises (SMEs)

SMEs will use cobots to automate dangerous or repetitive work as they grow more reasonably priced and easy to operate. This tendency will enable advanced robotics outside of major sectors, therefore encouraging smaller operations’ higher production.

Mobile and Autonomous Cobots

Beyond set workstations, cobots will be able to operate wherever within a facility thanks to autonomous navigation. In sectors including warehouses and healthcare, these mobile cobots will enable dynamic processes.

Human-Robot Synergy

The future will center on enhancing human-robot cooperation, fusing robotic accuracy with human ingenuity and problem-solving. Innovations will guarantee that cobots promote an easy working relationship and improve worker safety and output.

FANUC Collaborative Robots (Cobots): An Overview

Global pioneer in robotics and automation FANUC provides a selection of collaborative robots (cobots) meant to operate securely next to humans in industrial settings. Applications in production, assembly, packaging, and more fit FANUC cobots since they mix accuracy, safety, and simplicity of use.

Key Features:

- Safety: Advanced safety-certified sensors on FANUC cobots enable them to function free from cages or barriers when operating close to people.

- Versatility: With payload capabilities ranging from small components to heavy goods, they are built to manage chores including material handling, quality inspection, and machine tending.

- Ease of Use: Operators with little robotics knowledge can access FANUC cobots by hand-guided education and user-friendly interfaces, which enable simple programming.

- Durability: Reliable by nature, FANUC cobots are designed to withstand challenging industrial environments.

Popular FANUC Cobot Models:

- CR Series: Features cobots with varied payload capacity including the CR-4iA, CR-7iA, and CR-35iA (capable of handling up to 35 kg).

- CRX Series: Lightweight and energy-efficient cobots designed for easy deployment and collaborative work.

Because of their high-performance automation capabilities and smooth human-robot collaboration, FANUC’s cobots are trusted in sectors including automotive, electronics, and consumer products.

Human-Robot Collaboration (HRC): An Overview

Human-robot collaboration (HRC) is the interaction of people and robots cooperating to finish activities in common surroundings. Unlike conventional industrial robots that operate in confined environments, cobots—or cooperative robots—are made especially to securely and successfully interact with humans.

Key Features of HRC:

- Safety:Modern sensors and algorithms enable collaborative robots to recognize human presence and stop mishaps, therefore guaranteeing safe contact.

- Task Sharing: While humans concentrate on difficult decision-making and creative problem-solving, robots tackle repetitious or physically taxing chores.

- Ease of Use: Many cooperative systems are easily accessible for operators with little technical knowledge since they provide simple programming interfaces including hand-guided education.

- Flexibility: Small-batch manufacturing, assembly, and even customer-facing positions are suited for cobots since they can readily adapt to several activities.

Applications of Human-Robot Collaboration:

- Manufacturing: By helping with assembly lines, quality control, machine tending, cobots increase efficiency and lower worker fatigue.

- Healthcare: Robots help medical professionals with jobs such patient lifting, surgery aid, or rehabilitation exercises.

- Logistics: Working with warehouse employees, collaborative robots help with sorting, packing, and products movement.

- Research and Education: Robots help researchers or students so that hands-on learning and invention may flourish.

Benefits:

- Task automation increases production.

- better workplace ergonomics via lessening of worker physical strain.

- Improved operations’ quality and accuracy.

Challenges:

- Guaranturing user acceptance and confidence of robots in the workplace.

- Including robots into current procedures and educating staff members for teamwork.

- Dealing with safety and regulatory issues, particularly in high-risk settings.

Advances in artificial intelligence, sensors, and robotics are driving ongoing evolution in human-robot cooperation. It is absolutely essential for industries to be reshaped for higher innovation, flexibility, and efficiency.

Evolution of Collaborative Robots

The development of collaborative robots (cobots) exposes a notable change in robotics from conventional industrial automation to safe, human-centered cooperation. Their development is broken down here:

1. Early Beginnings (1990s)

- Aiming to construct robots that could help rather than replace humans, MIT and General Motors researchers first developed the idea of collaborative robots in the middle of the 1990s.

- Rising as a major contender in 1996, Universal Robots brought flexible, light-weight robots meant for direct human contact.

2. First Generation Cobots

- In the late 1990s and early 2000s, cobots lacked agency. These were basic mechanical tools meant to help with repeated chores or magnify human effort.

- Safety-oriented designs incorporated passive mechanisms guiding movement depending on human operation.

3. Advancements in Sensors and Safety (2000s)

- Better artificial intelligence (AI) and sensor technology let robots see their surroundings.

- Advanced capabilities for fine motor tasks and flexible deployment in sectors like electronics and assembly allow cobots like ABB’s YuMi (2015) and Rethink Robotics’ Baxter and Sawyer great appeal.

4. Mainstream Adoption (2010s)

- Cobots evolved in usability with hand-guided education and simple programming interfaces.

- Manufacturing, shipping, and healthcare were among the widely used industries as businesses looked for automated solutions that might complement staff members.

- With their reasonably priced and flexible solutions for small and medium-sized companies (SMEs), Universal Robots’ UR series dominated this era.

5. Integration of AI and Machine Learning (2020s)

- Modern cobots use artificial intelligence and machine learning to fit tasks and surroundings.

- Real-time object detection and autonomous decision-making made possible by advanced vision systems as those developed by Fanuc and Kuka allow for

- Mobile collaborative robots made it possible for them to move between workpaces free from fixed installations.

6. Current Trends and the Future

- Human-Robot Synergy: an emphasis on building flawless processes whereby robots improve human capacity.

- Sustainability: Designs with environmental consciousness stress energy economy.

- Broader Accessibility: Reduced prices allow cobots to be available to SMEs.

- Edge computing and 5G among other emerging technologies improve robot connectivity with other systems.

Cobots’ development shows a tendency toward ever intelligent, flexible, and easily available automation, hence changing businesses into safer and more efficient environments.

Conclusion

By increasing production, enhancing workplace safety, and letting human workers concentrate on creative and high-value jobs, collaborative robots—cobots—are transforming sectors. These robots guarantee consistency and efficiency by excelling at repeated, exact, or hazardous tasks, therefore allowing a safer workplace.

Cobots are getting smarter and more user-friendly as artificial intelligence, machine learning, and sensory technologies develop—they are perfect partners for people. From big companies to small firms, their increasing price and adaptability make them more easily available to companies of all kinds.

With mobility, autonomy, and human-robot interaction opening the path for even more amazing cooperation, cobots show great promise going forward. Now is the chance to investigate how using cobots might improve processes and stimulate creativity in your company. Using collaborative robots will help your company to become smarter and more efficient, so releasing their ability to design a better future.